making mycelium material – some loose protocols

Supplies:

grain spawn (many are fast growing; Pleurotus (oyster muchroom) is probably the fastest species, and is hardy, in terms of resistance to competition, but it will depend on the density you desire). You can purchase from mycosense, fungi.com, etc. I recommend mycosense because they are a small attentive company, and they are really into this process and work.

100 cup coffeemaker with a thermometer is convenient

but a large canning pot on a stove would do

nut bags (or other mesh bags) to pasteurize substrate (easy to squeeze water out)

a press to squeeze substrate would be nice, esp if you are making a lot of it

substrate: coffee chaff, oat straw, rice husks – depends on texture you want

molds to form substrate (I’ve been making test bricks in hinged polyethylene containers)

will need to provide an air hole

polyfill or cotton bags to make an air filter fo the hole – keep contaminants out

zip locks (if you are using a very porous mold (i like perforated molds for texture) you will want to place porous mold in a zip lock to keep moisture in

freezer tape and sharpie to label molds

spray bottle with 70% alcohol (should be 70% – you don’t want to kill everything)

paper towels or alcohol wipes

vinyl disposable gloves

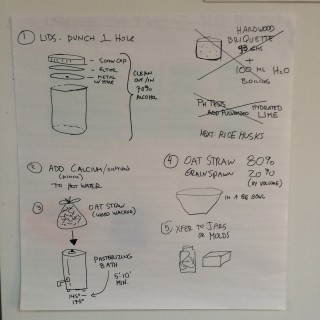

Steps:

heat water to 160º

pasteurize substrate for 10-15 minutes

clean all work surfaces and mold interior and exterior with alcohol and dry

wash hands and arms with soap, wear gloves for the next steps:

cool substrate until you can handle it

squeeze all excess water from substrate (you want it moist but not dripping at all)

put air filter into hole in mold

mix grain spawn with substrate; there are 2 ways to do this:

“lasagna” method of layering substrate then spawn, or

premix 1:5 spawn:substrate

either way, the ratio is about 20%, might be less needed

pack mold with spawn

keep somewhere between 70º – 80º

(I keep my molds in a loosely closed cardboard box to prevent contaminants drifting in the air or falling from the ceiling)

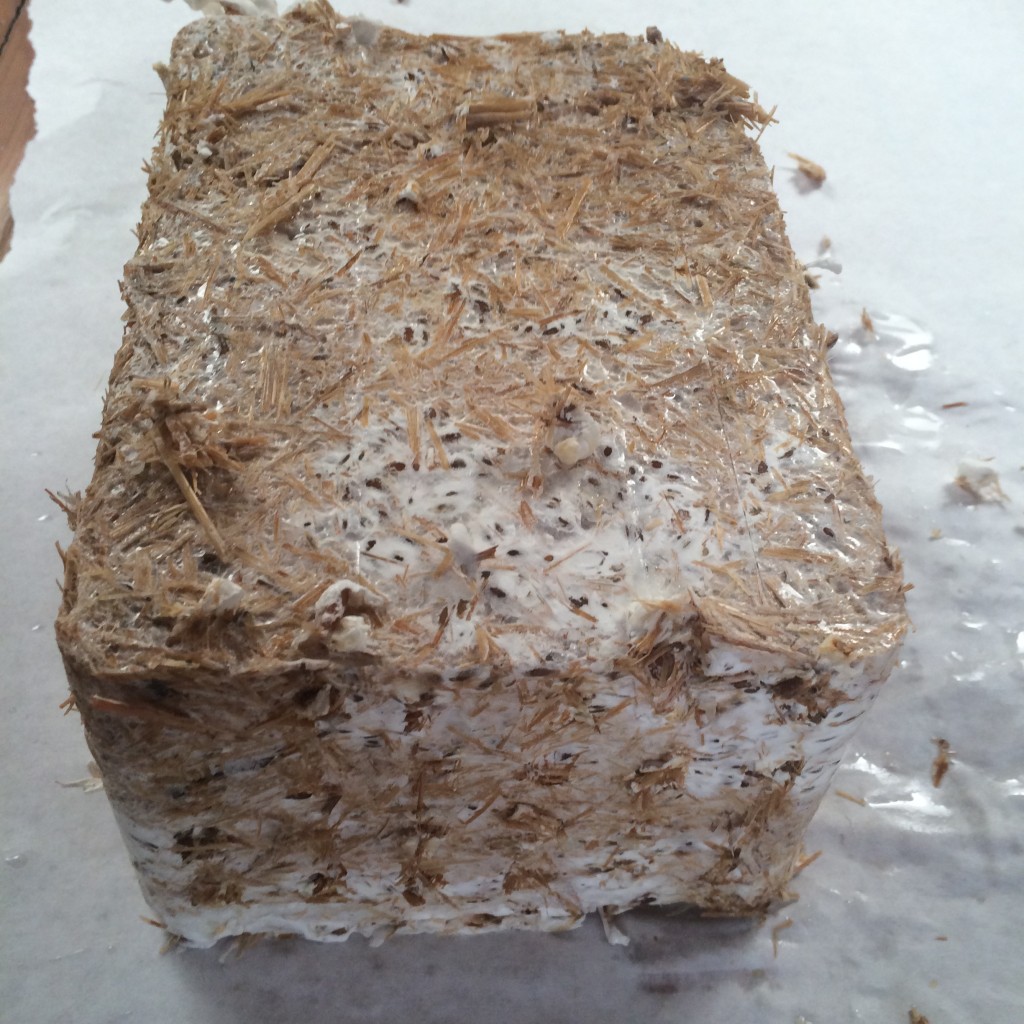

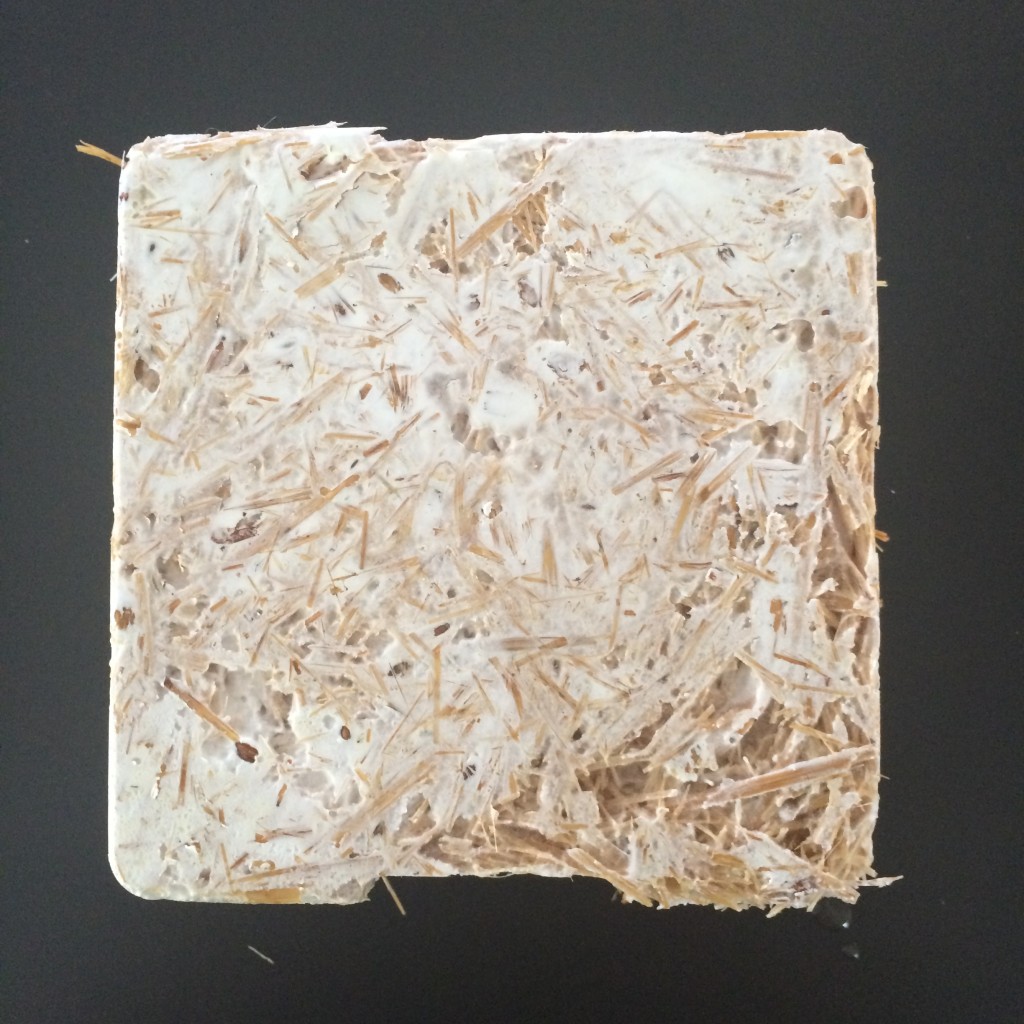

You should have a pretty solid material after 6-12 days

It will look very white and fuzzy

Remove from mold

Dry in open air (it should no longer risk contamination at this point) for 3 days or until dry to touch

Bake in over at 150• – 200º for 60 minutes to render mycelium inert.

Inoculation

I’m learning how to grow mycelium materials.

First, a big shout out to Phil Ross for teaching workshops about this process, and for being a pioneer willing to share.

Here are some janky documentation images of my process (with support and help from Jon Salmon of Mycosense and Sara Huston of TLAAG). I’ll get a more orderly post together soon.

Jon Salmon of Mycosense Mushrooms and Sara Huston of TLAAG.

Oat straw, a coffee maker to pasteurize, some 70% alcohol, Pleurotus ostreotis spawn on grain

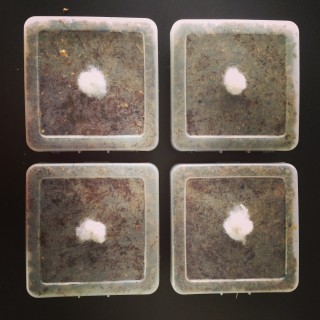

DAY 3:

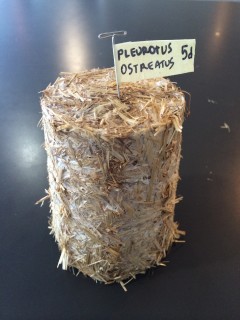

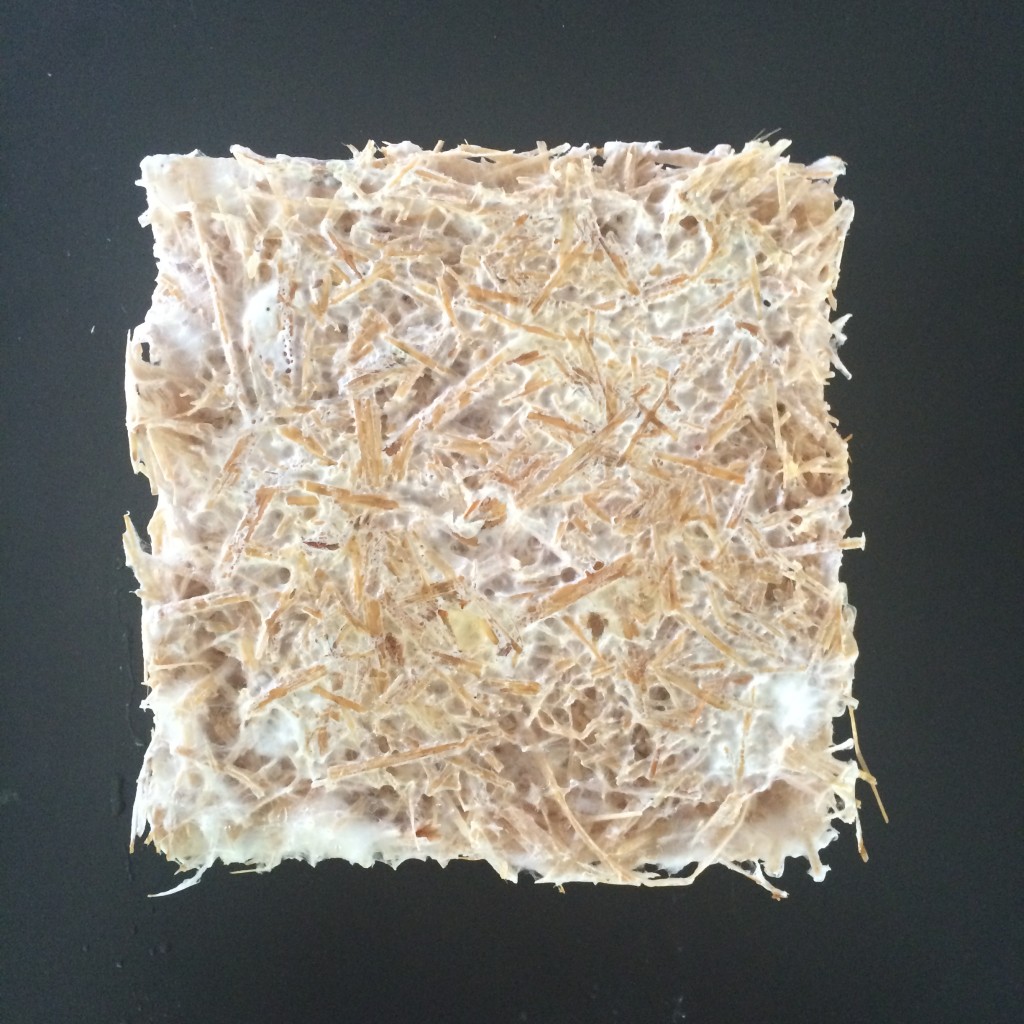

DAY 5:

Day 7:

Cuisinart to make the oat straw finer didn’t work so well. The plastic containers are molds for brick samples, and in the black pot there’s oat straw in nut milk bags that I pasteurized in a 100 cup coffee pot.

Transferred jar contents to bricks and cylinders.

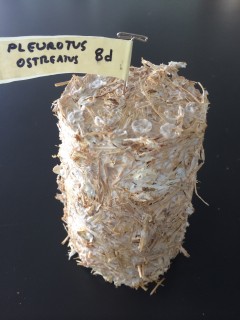

Got the first cylinder out after 6 days of Pleurotus ostreatus, and it is pretty solid.

The second cylinder of Pleurotus ostreatus eating oat straw, left in the mold for 8 days

And new substrate /species combos

Coffee chaff with Wood ear (Auricularia auricula-judae)

Oyster (Pleurotus ostreatus)

We doubt that the wood ear will have enough mycelium presence to adhere the material together, but it does grow fast.

Jon Salmon!

new bricks: 7/30

new species: ganoderma/reishi:

Houseboats

So… my PDX project’s gone through some shifts in the last 3 weeks.

I lost my design partners, but gained them as consultants! and some great new allies have appeared.

I have a new name for the project, and a framework of a project that suggests a permanent floating studio, less of a sculpture-centric temporary artwork:

Floating Studio for Dark Ecologies (FSDE) is an art/science residency program and public artwork to be sited on a houseboat on the Willamette/Columbia Rivers (Portland, OR). FSDE integrates social practice, craft, and citizen science to address the confluence of social, biological and economic systems connecting climate change and river health.

FSDE residents will investigate the “dark ecology” of North Portland (“green” mecca and home to 11 long-term superfund sites) and examine the science, politics, poetics and pragmatics of the rivers.

At the center of the floating studio is a small chai house fusing curiosity, hospitality, and action. Guests will produce and drink tea mirroring the environment: geology (clay cups), water, plants (chai spices), and black tea (imported from across the Pacific). This intimate ritual connects local and global concerns of climate, citizenship and the ecosystem in order to imagine and shape the rivers’ future.

+++

This means…

get a houseboat

modify, upgrade and customize

rent moorage

I met with the sublime and elegant Diane Hall, ED of the Bill Healey Foundation yesterday. She and her sister live on next-dock-neighbor houseboats. I got some tips on what to look for: old growth logs are best. You can really revamp a boat in a big way and even grow trees.

++++

Yesterday I also met with Peter McCoy, the founder of Radical Mycology: he is a force in the remediation world. Open source, DIY, generosity model, passionate, theoretical, speculative, and really knowledgable.

Peter and Oliver Kellhammer will be leading a design charrette with me in PDX at the end of July, on using bio-remediating materials in architecture, art and design.

Ian McHarg on environment, multidisciplinarity and time

fishery collapses

As part of SSC’s inaugural tasting and brainstorm event, I made a new version of a jellyfish granita that Lucullan Foods and I developed at Rice U in March.

We decided to top the granita with a sweet sashimi – we wanted local geoduck clam, but couldn’t get any, so went with Kampachi (“boutique yellowtail) which is responsibly farmed in Hawaii. I admit this isn’t the most rigorous menu decision.

The web page of kampachifarm.com, one of the aquaculture producers has some horrifying fishery collapse statistics, like this one:

I appreciate kampachifarm.com‘s commitment to responsible production. Their web site has extensive information. But there are serious oversights and gaps in the base assumptions that we must eat fish, that demand for healthy omega-rich seafood is escalating (population increases, access to global products to name just 2) , and that in order to save the ocean’s wild fisheries, we must farm and do so in ways that do not put more pressure on the ocean ecosystem. And as we move away from wild-caught feedstock (it’s getting scarce and prices have soared) for these farmed fish, we need to feed them a high protein substitute grown on land… like… SOY. Wait… isn’t that also a problem? Sounds like monoculture support or at least, elision of how soy aggravates land-based environmental poverty.

Lastly, when I savor my tiny, tony sliver of kampachi tonight, I want think about the life this fish had in this sea-bound ball: